MIL-DTL-62462D(AT)

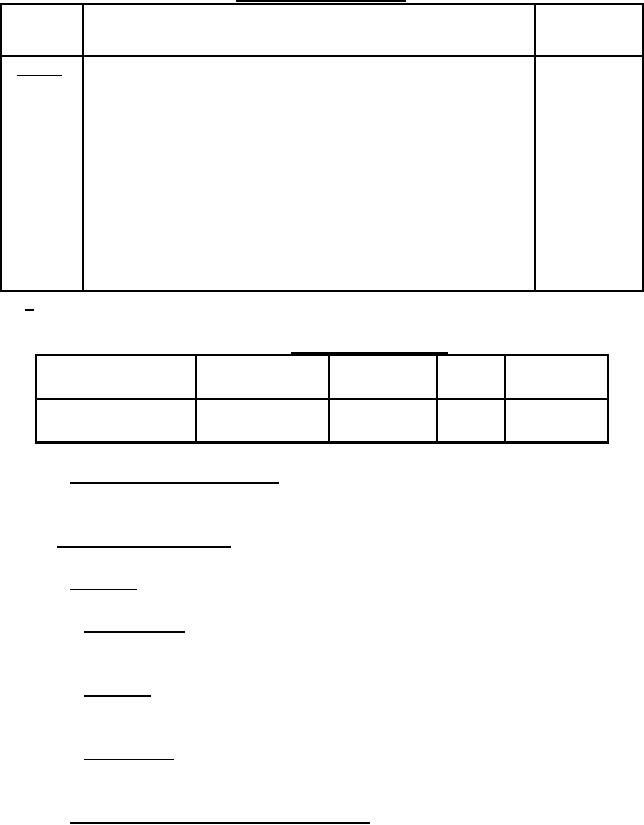

TABLE II. Classification of defects - Continued.

Method of

examination

Category

Defect

Minor:

201

Fuel lines: damaged, rubbing, improper support.

Visual

202

Oil dipstick gage: missing.

Visual

203

Oil level: overfilled, below safe operating level.

Visual

204

Bolt on components loose; nuts or bolts missing, heads

Visual and

rounded or deformed.

tactile

205

Threaded holes: incorrect size, improper depth.

SIE

206

Identification, instruction, data, and name plates: missing

Visual

or incorrect.

207

Painting: sags, runs, inadequate or improper coverage,

Visual

paint in threaded holes.

1/ SIE = Standard Inspection Equipment.

TABLE III. Classification of tests.

First

Acceptance

Title

Requirement

Inspection

article

(100%)

Leakage

3.3.3

4.5.1

X

X

Environmental

3.3.4

4.5.2

X

4.3.3 First article inspection failure. Failure of any first article sample to pass specified

examinations or tests shall be cause for rejection.

4.4 Conformance inspection. Conformance inspections are classified as acceptance tests.

4.4.1 Sampling.

4.4.1.1 Lot formation. An inspection lot shall consist of all the diesel engines from an

identifiable production period, from one manufacturer, submitted at one time for acceptance.

4.4.1.2 Sampling. Samples for conformance inspection shall be selected in accordance

with general inspection level II of ANSI Z1.4.

4.4.1.3 Examination. For examination purposes, defects shall be classified as listed in

table II.

4.4.2 Acceptance tests (100 percent inspection). Each engine assembly shall be subjected

to examination for major defects 110 through 113, 117 through 120, and 123 listed in table II and

the tests specified in table III.

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business