MIL-PRF-62140B

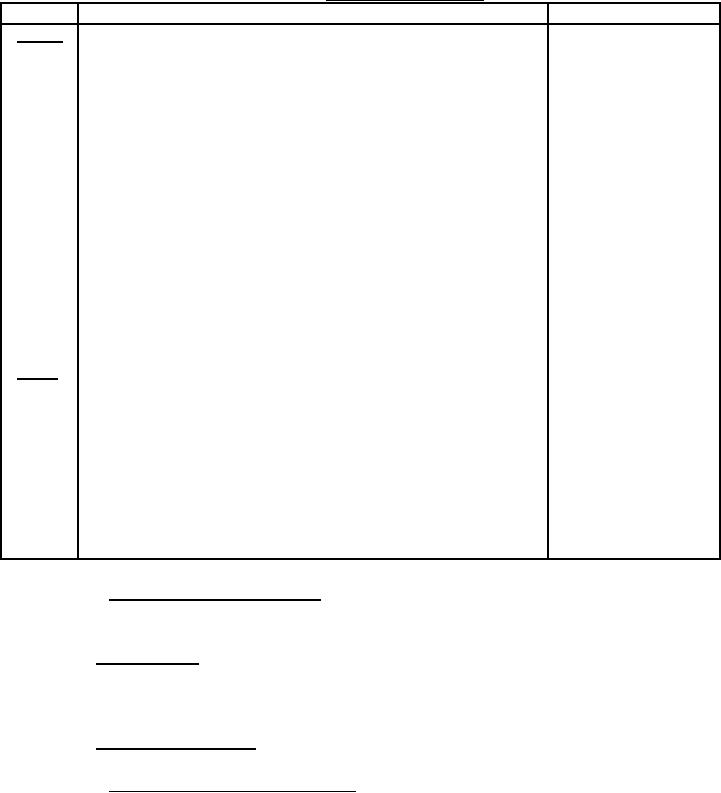

TABLE IV. Classification of defects.

Category

Defect

Method of examination

Major:

101

Gage

Exhaust valve tappet clearance - improper adjustment (see 3.3).

Visual and functional

102

Oil sump; fuel and oil filters - dirt, chips, or foreign objects (see 3.3).

103

Fuel, oil, and coolant - leakage (see 3.3).

Visual

104

Fuel lines - damaged (see 3.3).

Visual and functional

105

Visual and functional

Fuel system components - malfunction, damaged, or leaks (see 3.3).

Gage and functional

106

Fuel injection system, timing, and components - malfunction,

improper adjustment (see 3.3).

107

Cylinder head bolts, intake and exhaust manifold flange bolts, and

Torque wrench

vibration damper bolts - improper torque (see 3.3).

Crankshaft - excessive or restrictive end play (see 3.3).

Gage and functional

108

Gage

109

Crankshaft pressure - exceeds limits (see 3.3).

Functional

110

Air cleaner - malfunction (see 3.3).

111

Air box pressure - exceeds limits (see 3.3).

Gage

112

Visual and functional

Governor - malfunction (see 3.4.2.1).

113

Workmanship - faulty affecting performance(see 3.8).

Visual and functional

Minor:

Linkage - improper adjustment (see 3.3).

Visual

201

Visual

202

Minor assemblies - omitted (see 3.3).

203

Engine - improper adjustment or installation of components (see 3.3).

Visual and functional

204

Fuel lines, hose, vents, and shut-off valve - improper assembly or

Visual

installation (see 3.3).

Exterior surface treatment - improper application (see 3.6).

Visual

205

Visual

206

Corrosion - appearance of damage (see 3.6).

Visual

206

Plates - improper (see 3.7).

207

Workmanship - faulty affecting appearance (see 3.8).

Visual

4.4.2 Conformance inspection tests. Subsequent to the examination of 4.4.1, the sample

engines shall be subjected to the conformance inspection tests specified in table III.

4.5 Control Tests. Control test sample(s) shall be new and examined in accordance with

4.4.1 prior to being subject to the control tests (see table III and 4.6.4.2). Sample size and

frequence of tests shall be specified in the contract (see 6.2).

4.6 Methods of inspection.

4.6.1 Materials, design and construction. Conformance to 3.2 through 3.3.2 shall be

determined by inspection of contractor records providing proof or certification that design,

construction, processing, and materials conform to requirements. Applicable records shall include

drawings, specifications, design data, receiving records, processing and quality control standards,

vendor catalogs and certifications, industry standards, test reports, and rating data.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business