MIL-PRF-62541A

4.5.3.4 Exhaust smoke density. To determine conformance to 3.4.6, exhaust smoke

density shall be measured by a standard smoke meter. Table III may be used to visually define the

degree of exhaust smoke density in lieu of a smoke meter. Observation of exhaust smoke shall be

made against a white background within 3 ft of the turbocharger outlet.

TABLE III Exhaust smoke density.

Description of exhaust smoke Classification

Clear

1

Haze

2

Light Gray

3

Medium Gray

4

Dark Gray to Black

5

4.5.3.5 Oil consumption. To determine conformance to 3.4.7, the engine shall be

operated on the dynamometer for 25 hr at full rack.

4.5.3.6 Oil pressure. To determine conformance to 3.4.8, the engine shall be operated at

2800 rpm, with oil sump temperature range from 230 to 250°F. The engine shall be idled as

specified in 3.4.3, with an oil sump temperature range from 180 to 230°F.

4.5.3.7 Endurance. To determine conformance to 3.4.9, the following test shall be

performed. The endurance test shall be 400 hr, consisting of four periods of 100 hr each. Each

100 hr period shall be made of ten 10 hr cycles, with each cycle in accordance with table IV.

Running time less than 30 minutes shall not be counted toward fulfillment of the 400 endurance hr

unless it is specified in table IV.

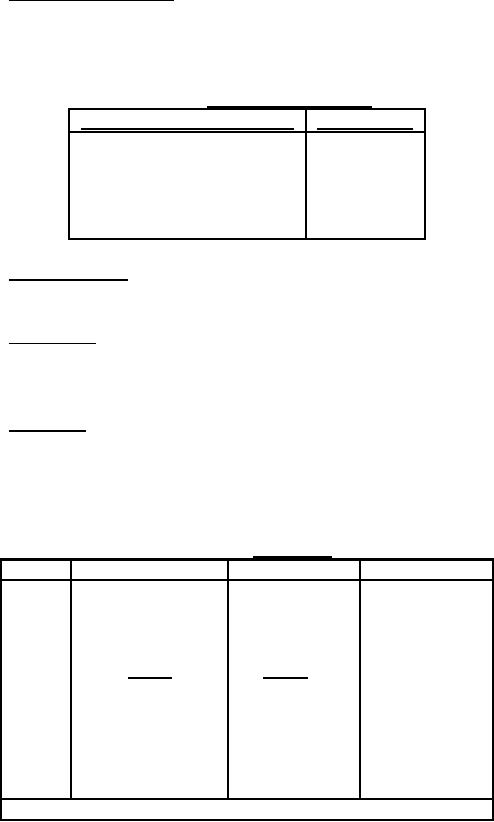

TABLE IV. 10 hr cycle.

Period

% Rated speed

% Load

Duration hours

0

1

Idle

1/2

100

2

100

2

3

Governed speed

0

1/2

4

75

100

1

0

100

2

5

Idle

100

4 min. 6 min.

6

60

100

1/2

7

Idle

0

1/2

Governed speed

70

1/2

8

Max. torque speed

100

2

9

60

50

1/2

10

Total duration:

10

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business