MIL-DTL-62177E

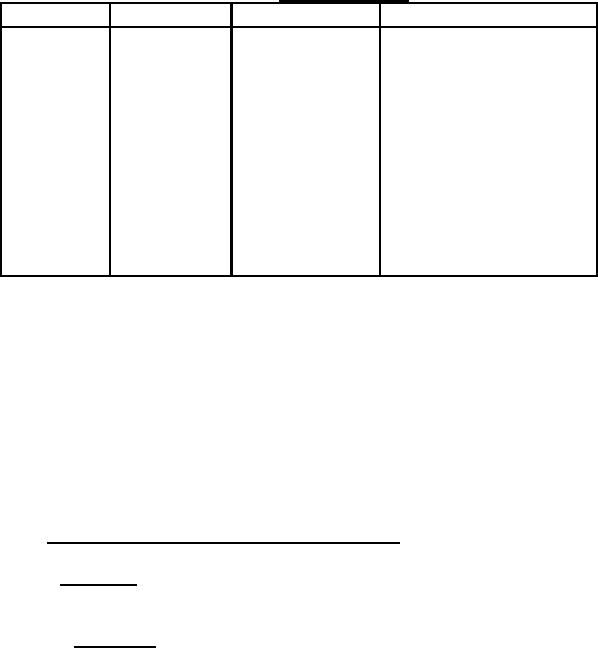

TABLE VI. Break-in schedule.

Torque lb ft (N⋅m)

Run number

Time minutes

Speed rpm

1

10

Idle 700-750

Warm up

2

15

1000

85 (115)

3

15

1400

440 (597)

4

20

1800

837 (1135)

5

20

2200

1024 (1389)

6

20

2400

1092 (1481)

7

30

2400

1202 (1630)

8

30

2400

Full power setting

9

5

2400

Full power setting

10

5

2200

Full power setting

11

5

2000

Full power setting

12

5

1800

Full power setting

NOTES:

-Bare engine shall operate without generator (see 6.5).

-Basic engine shall operate with alternator and field excitation only (see 6.5).

-Engine shall operate on its designed oil system, not on a test cell oil system.

-Check for low idle at 700 to 750 rpm - adjust if necessary.

-Inspect visually for air, exhaust, oil, and fuel leaks.

-Check governor high idle speed at 2600 to 2660 rpm (no load, dynamometer

water off). If adjustment is required, recheck the horsepower at 1800 and

2400 rpm at the full power setting.

-The governor shall be resealed after adjustment.

4.6.4 Support and ownership requirements verification.

4.6.4.1 Endurance. To determine conformance to 3.5.1, the engine shall be subjected to

an applicable test as follows.

4.6.4.1.1 First article. The engine shall be tested as specified in table VII for 20 cycles.

The engine shall require only minor services (such as replacing oil or fuel filter elements) during

these runs. Adjustments or replacement of parts must have approval by the Government. The

test shall be conducted under the following conditions:

a. Running time less than 30 minutes shall not be counted toward the fulfillment of

endurance hours.

b. The inlet air temperature shall be not less than 60°F nor more than 100°F.

15

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business